Toilets are still based on the original design from over a century ago.

This basically works pretty well, but the shapes have evolved through the years and today flushing efficiency is good and also reliable, and household plumbing and drainage is now designed to accommodate the requirements of the modern toilet. In simple terms the requirements are a water supply in and a wide diameter (around 100mm or 4") outlet pipe drain the effluent away. The design employs a "water trap" to prevent nasty odours escaping from the sewer back into your bathroom.

Lets look at the basics:

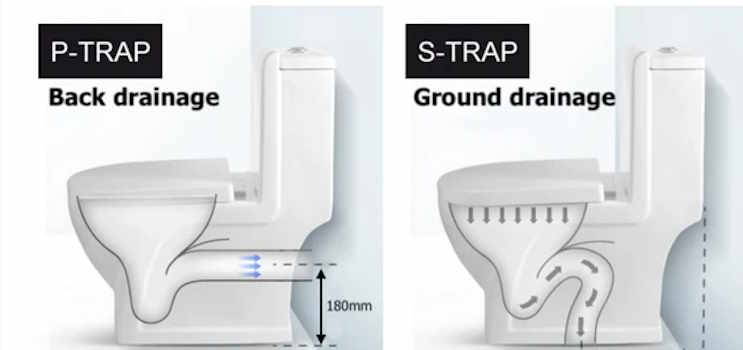

P-trap and S-trap refer to the shape and orientation of the trap that connects the toilet bowl to the waste pipe.

The original toilet design used an S trap as illustrated. You can see that the waste outlet in this type is below the toilet installation and the flow out from the pan is via an S shaped pipe moulded into the ceramic body of the toilet. Newer designs employ the P trap where the waste flows out from behind.

So what's the difference in practical terms?

A P-trap toilet has a trap that is shaped like a "P". It is a curved pipe that is designed to hold water and create a barrier between the toilet bowl and the waste pipe. The water in the P-trap prevents sewer gases from entering the room, as the gases are unable to flow back up through the trap. P-trap toilets are more common in modern construction and renovations, as they are more effective in preventing odors and are easier to maintain.

An S-trap toilet has a trap that is shaped like an "S", having a straight pipe that connects the toilet bowl to the waste pipe, and the trap is formed by a bend in the pipe just below the toilet bowl.

In general, P-trap toilets are the preferred option due to their ease of maintenance, and while the S-trap toilet can flush effectively because the design causes a siphon action the internal moulding in the ceramic has more bends which can be more prone to blockage. P trap designs tend to use less water which also makes a more attractive option these days.

Plumbing a P trap to a floor outlet:

In most circumstances this can be quite easily achieved by using a 90degree bend pan connector, or a swan-neck pan connector. These push onto the outlet at the rear of the toilet and bend down to connect into the waste pipe on the floor.

There can be circumstances where the waste connection in the floor is too far from the wall behind to allow even the swan neck connector to fit. If the floor is timber it might be possible to reposition the waste pipe, but in a concrete floor this is clearly more difficult, and of course will add expense to the job. A simple solution is to build a small timber box section behind the toilet, reducing the distance between wall and waste outlet and allowing the pipework to connect. The resulting box can be tiled or clad in whatever material is being used, thus blending into the background.

Unfortunately the opposite is not possible without major work. If the plumbing in your bathroom is set up for a P trap toilet it will be almost impossible to fit an S trap, although I can't really think why you might want to do this.

Flushing systems.

In simple terms the waste is flushed from the toilet bowl by a rush of water into the pan which pushes everything into the outlet pipe through the trap. This simple mechanism is called wash down. There is an alternative known as siphonic which is only possible with the S trap design. In this design the natural siphon effect of the S trap is enhanced by the addition of water directly into the top of the S bend. When the toilet is flushed water rushes into the pan, but also through a second valve into the S bend which starts the trap siphoning, so waste is both pushed and pulled from the pan. These flush systems tend to be quieter than the wash down, but use more water so in many countries the desire to reduce water consumption has led to the fitting of wash down toilets only. Another reason for the decline in siphonic toilets is the cost, wash down systems costing less.

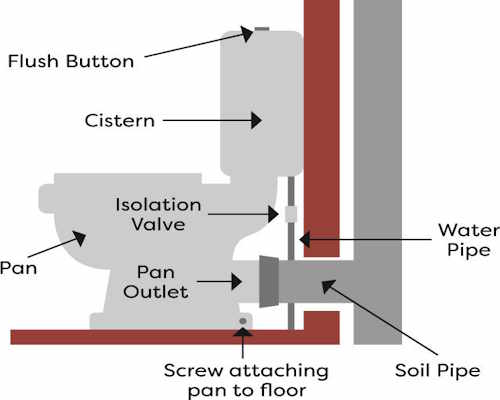

This diagram shows the parts of a close coupled toilet, where the cistern is attached directly onto the pan. Other variants exist where the cistern is separate and attached by a pipe, and in some cases the cistern is concealed behind a wall or piece of furniture.

Flushing water is stored in the cistern and when the flush button is pushed the water is released through the flush valve and flows into the pan. Often there are holes around the top edge of the pan through which the flush water enters, but in recent years the rimless pan has been developed where water enters at the back of the pan and is directed around the sides of the bowl creating a venturi effect to ensure the sides of the bowl are efficiently cleaned.

The water pipe shown above is the feed into the cistern and it can be closed using the isolation valve to shut down the water supply if any maintenance is required. The soil pipe takes the waste away to the sewer when the toilet is flushed. Notice that the soil pipe extends upwards as well as down to the drains. This is an important feature as the soil pipe needs to open to the atmosphere to allow air into the drain system and avoid a vacuum being caused by the waste water being flushed through to the sewer. Such a vacuum could prevent the toilet flushing correctly.

see more about toilet installation