The facts about bath construction and materials

There are many different manufacturing techniques and materials used in the construction of a modern bath. Originally baths were made from cast iron, the molten metal cast in a mold and enameled inside to give a smooth finish. This method produced a strong bath which tended to keep the bath water reasonably warm, but which was very heavy and limited in the styles and shapes available. Today the arrival of more modern materials has enabled the production of an almost limitless range of shapes and styles, yet cast iron still remains an option, and a fairly popular option too.

Acrylic

Acrylic offers the most versatile material for producing bath tubs in intricate shapes and interesting styles and so is the most widely available bath type in today's marketplace.

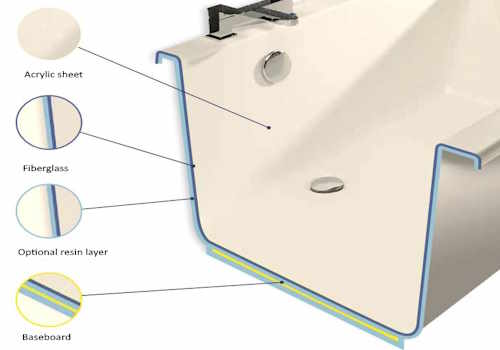

This type of bath is vacuum formed from a sheet of acrylic material. The sheet is heated and becomes very pliable, is placed onto a mold, the air is pumped out from below the sheet and it is basically sucked into shape. The acrylic sheet can be formed into simple of complex shapes by this method, giving the massive range of shapes and styles which are available. However the process also causes the acrylic sheet to become quite thin in places so it needs to be reinforced to provide strength. A layer of fiberglass is applied to the underside of the bath and a baseboard is bonded onto the bottom, giving strength and rigidity. The baseboard also offers a secure mounting for the bath legs and adjustable feet.

Higher quality acrylic baths have a further layer of fiberglass applied after the baseboard is fitted, offering even greater strength. This is called a "fully encapsulated" baseboard.

In the very best acrylic baths a resin layer is added after the fiberglass to provide the strongest and most rigid tub, and also to give a finished surface on the outside of the bath. This is the way many free standing baths are constructed where the outer surface of the tub will be visible and so needs to be finished. Most manufacturers have their own registered trade name for this process, and while the formulation of the outer material will differ from one to another, the basic principal of construction is the same.

Pros and Cons.

Acrylic sheet provides a good looking, easily maintained bath tub, with a hygienic surface. Strength and rigidity is acceptable at the entry level and improves greatly in the slightly more expensive baths. In general however acrylic baths are reasonably priced. They are lightweight and easy to handle at installation. The acrylic material is a good insulator and thus water temperature can be retained for some time.

The surface of an acrylic tub can scratch, but on the up side scratches can be easily repaired. Even fairly big chips can be repaired without too much trouble.

Care must be taken at installation to avoid movement of the bath while in use.

Pressed Steel

Cast Iron

Decorative Metals

Solid Surface (Cast Stone)

Solid Stone